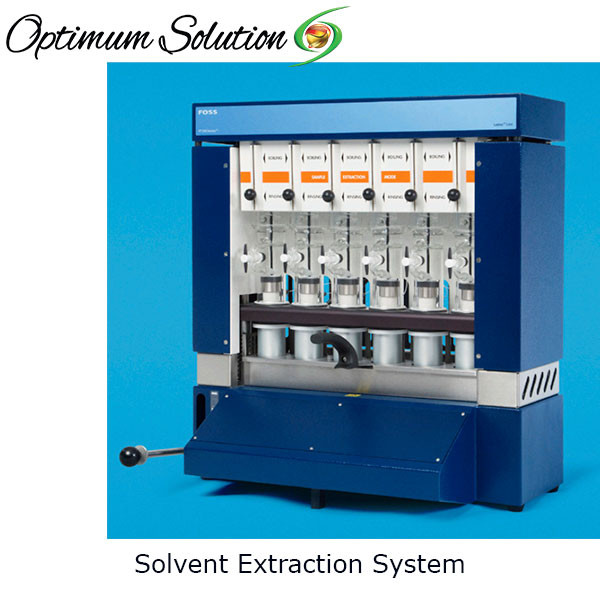

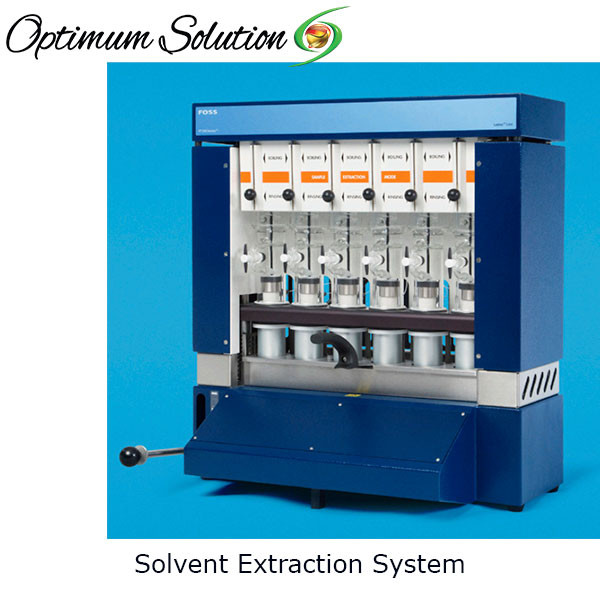

Fat Extractor Unit: Solvent Extraction System – 6-Position Soxhlet Apparatus Capacity, 0.1-100% Fat Range

Inhouse product

-

৳749,995.00

৳750,000.00 -

৳29,999,995.00

৳30,000,000.00 -

৳12,995.00

৳13,000.00 -

৳2,099,995.00

৳2,100,000.00 -

৳19,495.00

৳19,500.00

Reviews & Ratings

Fat

Extractor Unit: Solvent Extraction System – 6-Position Soxhlet Apparatus Capacity,

0.1-100% Fat Range

Struggling with traditional

Soxhlet extraction that takes all night and consumes excessive solvent? Are

safety concerns with flammable solvents limiting your lab’s productivity?

The Foss Soxtec™ ST 243 Fat Extractor Unit provides the

modern, efficient, and safe solution for determining crude and total fat

content. This advanced solvent extraction system dramatically

accelerates the process while delivering the same precision as official

methods. Designed for quality control, research, and production labs in the

food, feed, and agricultural industries, this fat extractor unit is

the definitive choice for laboratories that require rapid, reliable, and

cost-effective results for samples like meat, grains, cereals, and pet food.

Engineered for speed without

sacrificing accuracy, the Fat Extractor Unit: Solvent Extraction System

– 6-Position Capacity, 0.1-100% Fat Range transforms a classic

analytical procedure into a modern, streamlined workflow.

Solve Key

Extraction Challenges with Modern Technology

Traditional fat analysis is

often the bottleneck in a lab, plagued by slow speeds, high costs, and safety

risks. The Soxtec™ ST 243 Fat Extractor Unit is specifically

engineered to overcome these persistent challenges.

· Dramatically Reduce

Analysis Time from Hours to Minutes: Legacy Soxhlet methods can

take 6 to 24 hours. The ST 243 completes a full batch

of 6 extractions in just 40 to 60 minutes, accelerating your workflow by a

factor of five. This remarkable reduction in extraction time enables

your lab to achieve a throughput of 30-36 samples per day, providing faster

results for critical quality decisions.

· Slash Solvent

Consumption and Disposal Costs: Conventional extraction

uses large, costly volumes of hazardous solvents. This innovative system uses a

minimal solvent volume of only 40-50 mL per batch and recovers

approximately 80% of that solvent for reuse. This intelligent

design of the economical fat analysis system significantly

reduces per-test costs and minimizes environmental waste.

· Enhance Lab

Safety with Integrated Risk Mitigation: The combination of

flammable solvents and high heat is a major safety concern. This unit is built

with a spark-proof hot plate and dual temperature sensors that

actively prevent the system from reaching the ignition point of any solvent,

ensuring a safe working environment for your technicians.

· Minimize

Manual Errors with Streamlined Workflow: Handling hot glassware and

transferring samples manually introduces variability and risk. The system includes

dedicated batch handling tools for cups and thimbles, reducing

direct contact and potential for error. This user-centric design of the easy-to-operate

Soxtec unit improves both reproducibility and operator confidence.

Core Benefits:

How This Extraction System Enhances Lab Performance

The Fat Extractor Unit:

Solvent Extraction System – 6-Position Capacity, 0.1-100% Fat Range delivers

measurable advantages that directly impact your lab’s efficiency, compliance,

and bottom line.

· Guaranteed

Accuracy and Full Regulatory Compliance: This system delivers speed

without compromising on quality. It is fully approved for key official

methods including AOAC 2003.05, 2003.06, 991.36 and ISO 1444, 11085, 6492.

With excellent reproducibility of ±1% relative across the

entire measuring range of 0.1% to 100% fat, this AOAC-compliant

fat extractor provides the reliable, defensible data you need.

· Proven Cost

Savings Through Efficient Operation: The economic benefits are

immediate and ongoing. Drastically lower solvent use reduces recurring

expenses, while faster throughput maximizes your lab’s capacity. This makes

the Foss Soxtec™ ST 243 a strategic investment that improves

your lab’s operational efficiency and return on investment.

· Versatile

Application Across Diverse Sample Types: Designed for a wide range

of sample matrices including raw materials, intermediates, and finished

products, this versatile system can handle everything from fatty meats and

processed foods to animal feed and cereals with a typical sample size

of 0.5 to 2 grams.

· Complete,

Ready-to-Run System for Immediate Productivity: The unit

is supplied as a complete kit, including the extraction unit, control unit, and

essential accessories like cups, thimbles, and seals. This comprehensive

package ensures your new laboratory fat extraction workstation is

operational immediately, eliminating setup delays.

Detailed

Technical Specifications

The performance of the Soxtec™

ST 243 Fat Extractor Unit is defined by precise and compliant

engineering specifications.

· Model: Soxtec™

ST 243

· Brand /

Manufacturer: Foss Analytical A/S, Denmark

· Batch

Capacity: 6 positions

· Typical

Extraction Time: 40 to 60 minutes per batch

· Typical Daily

Throughput: 30 to 36 samples

· Solvent Volume

per Batch: Approximately 40 to 50 mL

· Solvent

Recovery: Approximately 80%

· Sample Size

Range: 0.5 to 3 grams (0.5-2 g typical for total fat)

· Fat

Measurement Range: 0.1% to 100%

· Reproducibility: ±1%

relative (at 5-100% fat content)

· Maximum

Operating Temperature: Up to 285 °C

· Power Supply: 230 V,

50/60 Hz

· Power

Consumption: Approximately 1250 W

· Cooling Water

Flow Requirement: Approximately 2 liters per minute

· Required

Ventilation: Must be operated in a fume hood with a minimum airflow of

0.5 m/s

· Extraction

Unit Weight: Approximately 30 kg

· Extraction

Unit Dimensions (Width x Depth x Height): Approximately 570 x 350 x

580 mm

· Control Unit

Weight: Approximately 3 kg

· Control Unit

Dimensions (Width x Depth x Height): Approximately 280 x 230 x

190 mm

· Key Safety

Features: Spark-proof hot plate, dual temperature sensors for

ignition prevention.

· Compliant

Standards: AOAC 2003.05, 2003.06, 991.36; ISO 1444:1996, ISO

11085:2008, ISO 6492:1999.

Upgrade Your

Lab's Fat Analysis with Proven Efficiency

Move beyond slow, wasteful, and

risky manual methods. The Foss Soxtec™ ST 243 Fat Extractor Unit is

a proven global standard that enhances productivity, ensures safety, and

delivers the precise, compliant results required in modern analytical laboratories.

Ready to transform your fat

analysis workflow? Contact our specialists today to request a detailed

quotation, schedule a product demonstration, or discuss how the Fat

Extractor Unit: Solvent Extraction System – 6-Position Capacity, 0.1-100% Fat

Range can meet your specific testing needs.

FAQ

FOSS SOLVENT

EXTRACTION SYSTEM

ST 243

Soxtec™ / Labtec™ Line

Questions

& Answers

1. What is the typical time required to complete one full

fat extraction (FAT) cycle?

Answer:

A complete fat extraction cycle typically takes 40 to 60 minutes, depending on the

sample matrix, fat content, and selected extraction parameters (boiling,

rinsing, and recovery phases).

2. What sample quantity can be loaded per extraction

position?

Answer:

The system supports a typical

sample weight of 0.5–03 g for most food and feed samples. For

low-fat or bulky samples, the weight may be adjusted according to the thimble

size and method requirements.

3. How is the cooling system controlled? Is tap water

sufficient, or is a chiller required?

Answer:

The system uses water

cooling for solvent condensation. Under normal conditions, tap water is sufficient.

However, in regions with high summer water temperatures, the use of a recirculating chiller is recommended

to maintain efficient condensation and solvent recovery.

4. Are there any recognized standards for system

calibration, and what is the approximate cost?

Answer:

The system can be calibrated according to AOAC, ISO, AACC, and official laboratory validation

protocols. Calibration is generally performed using certified reference materials (CRM)

or gravimetric checks. The cost varies depending on the standard and service

provider, typically moderate

and manageable for routine lab operation.

5. How much tap water is required to run the system?

Answer:

Water consumption depends on runtime, but typically 1–2 liters per minute

during active cooling. Many laboratories reduce water usage by using a closed-loop recirculating chiller.

6. Is the system acceptable for audits by SGS, BSTI, FS

authorities, Islamic Foundation, and buyers?

Answer:

Yes. The ST 243 Soxtec™ system is widely accepted in laboratories audited by SGS, BSTI, food safety authorities,

Islamic Foundation (Halal), internal QA teams, and international buyers,

when operated according to validated methods.

7. Are Calibration, IQ, and OQ documents available?

Answer:

Yes. Calibration, IQ

(Installation Qualification), and OQ (Operational Qualification)

documentation can be provided by the supplier or qualified service partners to

support regulatory and audit requirements.

8. What consumables and spare parts are required for one

year of operation?

Answer:

Typical consumables include:

· Extraction thimbles

· Solvents (e.g.,

petroleum ether, hexane)

· Seals and gaskets

· Filter papers

Spare parts may include heating elements and tubing, depending on usage

frequency.

9. Can fat be extracted from milk powder using this system?

Answer:

Yes. The system is suitable for fat

extraction from milk powder, following standard methods such as

AOAC or ISO dairy fat

extraction protocols.

Should be using CELITE 545

10. How many times can extraction thimbles be reused?

Answer:

Thimbles can typically be reused 10–20

times, provided they are properly cleaned, dried, and remain

undamaged. Reuse depends on sample type and handling care.

11. How should extraction cup volume be selected relative

to sample volume?

Answer:

The extraction cup volume should be sufficient to allow complete solvent circulation and

boiling without overflow. The sample should not exceed one-third to one-half of the thimble

capacity (40 ml) for optimal extraction efficiency.

12. What is the typical extraction time for instant noodles

containing ~16% fat?

Answer:

For instant noodles with approximately 16%

fat, the extraction time is typically 40–60 minutes,

depending on solvent type and heating intensity.

13. What solvent is recommended for extracting fat from

instant noodles?

Answer:

Commonly recommended solvents include petroleum

ether or n-hexane, as specified by standard food fat extraction

methods.

14. How much solvent volume is required per test batch?

Answer:

Each extraction position typically requires 40 mL of solvent

15. How efficient is the solvent recovery system, and where

is the solvent stored after recovery?

Answer:

The solvent recovery efficiency is typically above 75%. Recovered solvent is

condensed and collected back into the extraction

cups or designated solvent containers for reuse.

16. Is the system fully automatic or semi-automatic?

Answer:

The ST 243 Soxtec™ is a semi-automatic

system. Heating, boiling, rinsing, and recovery are controlled

automatically, while sample loading, solvent filling, and final weighing are

performed manually.

17. What safety features are included in the system?

Answer:

Safety features include:

· Over-temperature

protection

· Solvent vapor

containment

· Efficient condenser

system

· Chemical-resistant

components

· Stable heating

control

18. What warranty and technical support are provided?

Answer:

The system is typically supplied with a standard

12-month warranty, with access to technical support, spare parts, and

optional annual maintenance services.

19. Can the system be used for environmental testing

applications?

Answer:

Yes. The system can be used for environmental

testing, including extraction of oils and fats from soil,

sludge, and environmental samples, using appropriate validated methods.

20. Is the system suitable for routine laboratory use with

high repeatability?

Answer:

Yes. The ST 243 Soxtec™ system is designed for routine, high-repeatability fat extraction,

offering consistent results, reduced solvent consumption, and reliable

long-term laboratory performance. sample capacity per day: 30/36 samples

Keywords: fat extractor unit, Soxtec ST 243, solvent extraction system, fat analysis equipment, crude fat analysis, Foss analytical, Soxhlet extraction, food testing lab equipment, feed analysis, AOAC method compliance.

Frequently Bought Products

-

৳749,995.00

৳750,000.00 -

৳29,999,995.00

৳30,000,000.00 -

৳12,995.00

৳13,000.00 -

৳2,099,995.00

৳2,100,000.00 -

৳19,495.00

৳19,500.00

Optimum Solution (OS4U) – Laboratory & Analytical Instruments Supplier in Bangladesh

Optimum Solution (OS4U) is a leading supplier of laboratory equipment, analytical instruments, and process control solutions in Bangladesh. Since our inception, we have built a strong presence in the industry, serving research labs, universities, pharmaceutical companies, and quality control laboratories nationwide. Through continuous dedication to improving our products and services, OS4U has earned the trust and loyalty of our valued clients.